Moody corporation uses a job order costing system – In the realm of cost accounting, Moody Corporation emerges as a frontrunner, employing a job order costing system to meticulously track costs associated with distinct projects. This system serves as the cornerstone of their financial operations, offering unparalleled visibility and control over project expenses.

Moody Corporation’s adoption of a job order costing system stems from the need to accurately capture and allocate costs for their diverse range of projects. Unlike process costing or activity-based costing systems, job order costing aligns costs directly with specific jobs or batches, ensuring precise cost tracking and enhanced decision-making.

Job Order Costing System Overview

A job order costing system is a costing system that accumulates and assigns costs to individual jobs or batches of production. It is used in industries where production is unique and distinct, such as construction, custom manufacturing, and job printing.

The system provides detailed cost information for each job, allowing managers to track costs and make informed decisions.

Unlike process costing, which accumulates costs for a continuous production process, job order costing accumulates costs for each specific job. This allows for more accurate costing and better control over production costs.

Moody Corporation’s Job Order Costing System

Moody Corporation is a custom furniture manufacturer that uses a job order costing system. Each piece of furniture is a unique job, and the company accumulates costs for each job separately.

The benefits of using a job order costing system for Moody Corporation include:

- Accurate costing of each job

- Better control over production costs

- Improved profitability

The challenges of using a job order costing system for Moody Corporation include:

- Increased administrative costs

- Complexity of the system

- Potential for errors

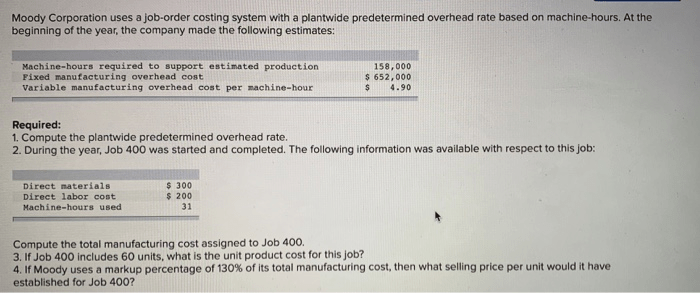

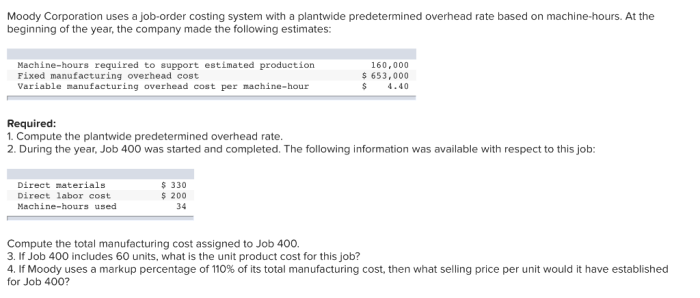

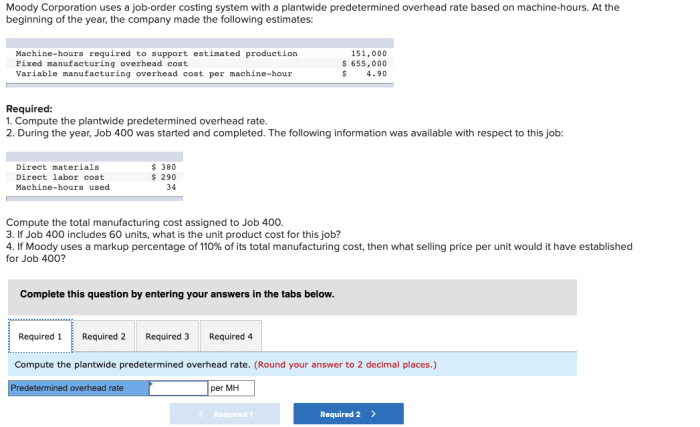

Cost Accumulation

The different costs that are accumulated in a job order costing system include:

- Direct material costs

- Direct labor costs

- Manufacturing overhead costs

Direct material costs are the costs of materials that are used directly in the production of a job. Direct labor costs are the costs of labor that is used directly in the production of a job. Manufacturing overhead costs are the costs of indirect materials, indirect labor, and other indirect costs that are incurred in the production of a job.

These costs are accumulated in a job cost sheet, which is a document that tracks the costs of each job.

Cost Assignment

Costs are assigned to jobs in a job order costing system using a variety of methods, including:

- Actual costing

- Estimated costing

- Standard costing

Actual costing assigns actual costs to jobs. Estimated costing assigns estimated costs to jobs. Standard costing assigns standard costs to jobs.

Moody Corporation uses actual costing to assign costs to jobs.

Job Costing Reports

The different types of job costing reports include:

- Job cost sheets

- Cost of goods manufactured schedules

- Income statements

Job cost sheets provide detailed cost information for each job. Cost of goods manufactured schedules summarize the costs of goods manufactured during a period. Income statements summarize the revenues and expenses of a company during a period.

Moody Corporation uses job cost sheets and cost of goods manufactured schedules to track the costs of its jobs.

Advantages and Disadvantages of Job Order Costing

The advantages of using a job order costing system include:

- Accurate costing of each job

- Better control over production costs

- Improved profitability

The disadvantages of using a job order costing system include:

- Increased administrative costs

- Complexity of the system

- Potential for errors

Alternatives to Job Order Costing

Moody Corporation could consider using a process costing system or an activity-based costing system as alternatives to a job order costing system.

A process costing system is a costing system that accumulates and assigns costs to processes rather than jobs. It is used in industries where production is continuous and repetitive, such as chemical processing and oil refining.

An activity-based costing system is a costing system that accumulates and assigns costs to activities rather than jobs or processes. It is used in industries where overhead costs are significant and difficult to assign to jobs or processes.

The advantages and disadvantages of each alternative should be carefully considered before making a decision.

FAQ Summary: Moody Corporation Uses A Job Order Costing System

What are the key benefits of using a job order costing system for Moody Corporation?

Moody Corporation benefits from enhanced cost accuracy, improved project profitability analysis, efficient resource allocation, and timely decision-making.

How does Moody Corporation accumulate costs in their job order costing system?

Moody Corporation accumulates costs by identifying direct materials, direct labor, and manufacturing overhead costs associated with each job.

What methods of cost assignment does Moody Corporation employ in their job order costing system?

Moody Corporation utilizes both actual costing and normal costing methods for cost assignment, depending on the nature of the costs and project requirements.